WeView's Intelligent Manufacturing

represents new quality and green productive forces

Manufacturing Capacity

Intelligent manufacturing is one of WeView's core technological advantages, featuring the most standardized, automated, digitized, and intelligent manufacturing system within the global flow battery industry. Since the commissioning of the world's first smart "Giga+ Factory" with over GW capacity in Zhuhai in 2023, WeView has continuously invested in research and iteration of its core intelligent manufacturing technologies, leveraging AI to enhance manufacturing equipment, processes, quality control, and production efficiency.

- The first automated production line in flow battery industry

- Over 30 intelligent manufacturing technologies with independent intellectual property rights

- Top-tier professional intelligent manufacturing team in the industry

- Establishment of a fully domestic supply chain

- L3.5 level of intelligent manufacturing

Automation

The fully automated dedicated production line for flow battery electrode plates achieves pressing, welding, lamination, shaping, and quality/performance testing of electrode plates without human intervention. With a production capacity of 15 plates per minute on a single line, it continuously produces the most critical component of flow batteries – the cell stack, achieving an exponential upgrade in battery consistency.

Efficiency

The cell stack assembly line seamlessly integrates six heavy-duty, 8-axis articulated robots, alongside numerous collaborative, parallel, and inverting robots, operating in perfect harmony. This setup enables a single production line to churn out fully assembled cell stacks, complete with quality checks, at a rate of one every 20 minutes. Incorporating a state-of-the-art laser-vision alignment and correction system, the precision of our industrial robots has seen a remarkable boost.

Integration

The industry's inaugural automated assembly line for flow energy storage systems marks a pivotal transition from engineering-centric processes to product-oriented manufacturing. Equipped with a streamlined intelligent manufacturing workflow, this line seamlessly integrates the assembly of chassis, structures, cell stacks, electronic controls, piping, and wiring harnesses. Furthermore, it leverages a suite of advanced automated inspection technologies to conduct intelligent quality checks across over 800 quality control points.

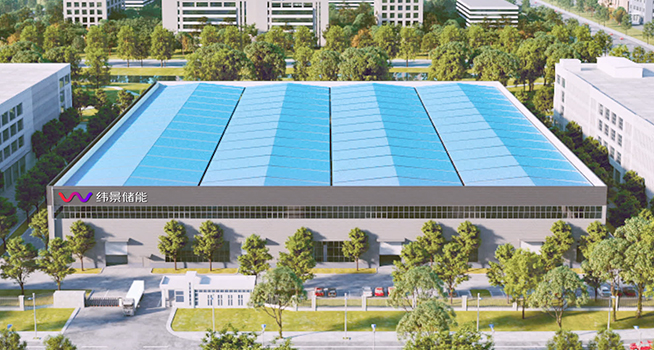

Zinc-iron flow battery "Giga+ factory"

Factories

Staffs

Domestic Components

Core Manufacturing Process

Manufactring Footprints

Giga+ Factory, Guangdong

World's first GW-scale flow battery intelligent manufacturing factory put into production

Giga+ Factory, Shandong

First full-chain GW-scale flow battery intelligent manufacturing base nationwide

Giga+ Factory, Hubei

Zinc-iron flow battery production line and energy storage power station integrated base

Pilot Production Line, Jiangsu

The first pilot production line and intelligent manufacturing base of zinc-iron flow battery